Im writing this in hopes to decrease the number of repetitive questions I get on a daily basis. I will start with, this swap is currently in the early stages with very little support and parts to make this a "bolt on and go" type of kit. I will also add, the slippery slope can be steep, leading to modifying, changing, and/or upgrading other components to support this system.

Lets get started-

We're using the BMW GS7D36SG which is a 7-speed Dual Clutch transmission designed for rear wheel drive applications. There are a couple different versions of this trans, but for most of our purpose we use the F80 DCT, which also has either a long or short ratio option.

Getting the trans in the car- Fitting inside the tunnel on some cars can be a little tight. May need to hammer or cut some material out to fit. On the S2000 we had to cut out some of the OEM trans mount bracing.

Mating the trans to the engine you will need an adapter plate and a flywheel hub adapter. Few companies are coming out with these parts of certain engines. I'd strongly try to find a reputable company here that has experience and even some real testing done before purchasing. We made our own adapter that uses an OEM manual trans flywheel on our S2000. We currently are NOT selling the adapter until we get some real track testing done (We prefer to test our products before releasing them to market).

On the other end of the transmission, you'll most likely need a custom driveshaft made. Most likely you'll need to get an adapter that will convert the BMW output flange to a 1350 flange. For driveshaft- We highly recommend Full Torque Driveshafts.

Trans mount- most likely need to be custom fabricated. This isn't too difficult for any well skilled fabricator with some kind of engineering mindset.

Electronics- This is the hardest part of making this trans work. I don't plan on getting into all the details, but here's a list of what needs to be done:

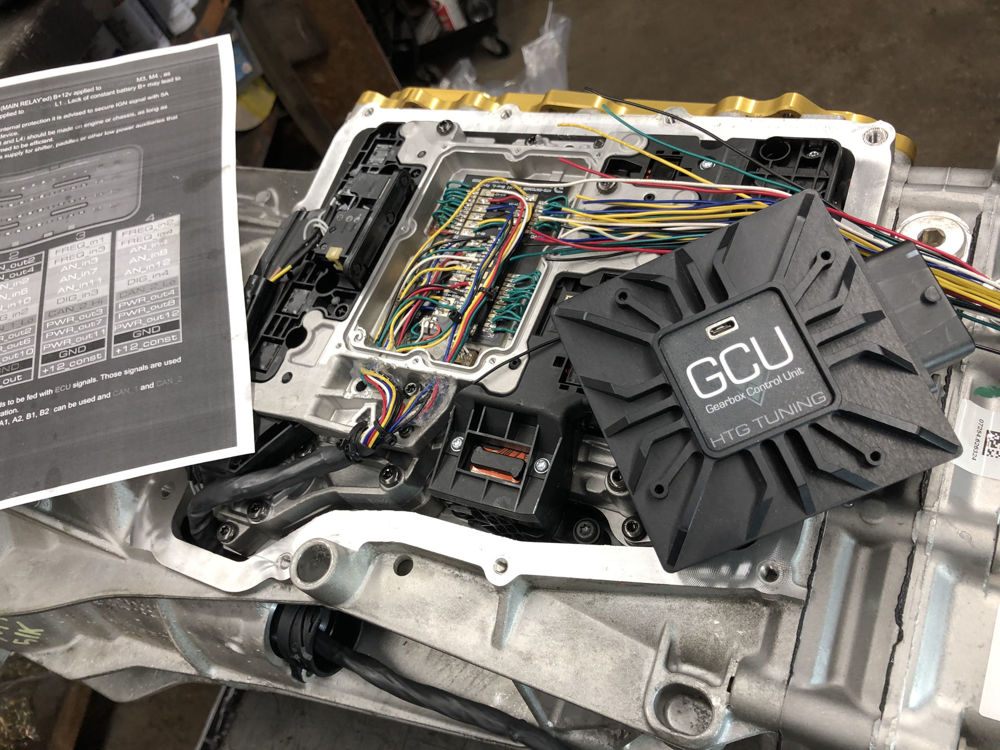

Gearbox Control Unit (GCU)- This we primarily use HTG Tuning.

Paddles/Mode Selector- Several options here. CAN Keypad for mode selecting. Any microswitch paddles.

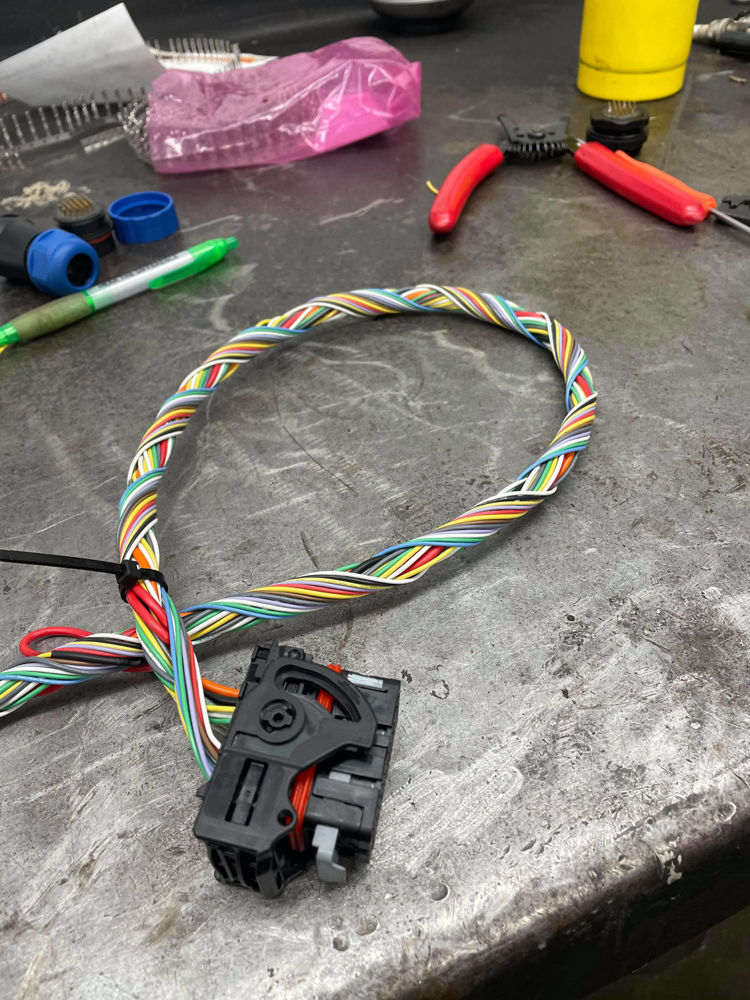

Wiring GCU to the Trans- This requires someone skilled with electronics and wiring. Lots of small soldering and pinning. The factory BMW GCU is inside the trans, so we basically need to hijack all sensors and solenoids and will be running them to our now external GCU. This job of wiring up a trans, running the harness to a bulkhead connector, then to the GCU is a full 1-2 day job and is by far the most critical part of the entire swap. One small mistake here and you will have a very goofy running transmission (if anything moves at all).

Integration- So now the trans is all wired up, we need to get lots of engine info to the GCU. This is better done over CAN. Ideally for best operation of trans, we want several inputs setup such as (not limited to)- RPM, TPS, MAP, Ignition, Lambda, Intake Temp, Coolant Temp, as well as brake pedal switch. There will also be a few outputs from the GCU. Two of them being a way to cut engine power (can be done in several ways), and a way to bring the rpm up under downshifts (again can be done in many ways). This will require an ECU capable of these functions. While these things are not truly "NEEDED" for the trans to work, they are needed to make quick and smooth up/down shifts.

Trans Tuning- So everything is connected, reading correctly, and all basic functions tested. Now we need to start tuning it all. Lots of things to do here and to achieve OEM type drivability, it can take days to dial in everything correctly. Tuning the initial engagement from a stop, smooth yet quick shifting under all different loads, downshifting, setting up pre-selection tables, setting up the "FULL Auto" mode, setting up safeties, plus much more if desired.

Other options-

Trans parking brake- Most just do a lockout of this, but this can be setup to work using the OEM BMW actuator.

Oil Pan- The OEM BMW pan is plastic and is known to crack pretty easy. Few companies make nice billet pans now.

Oil Cooler- Few companies make adapters for 8an outputs and you'll run to your own cooler.

COST- This is by far our number one question. This is not a simple mod, and is really hard to tell someone a price until we know more information. What car is this going in? What Engine and what power? What's the intended use? What ECU do you have? Driveshaft- Steel, Aluminum, Carbon?

There are just too many variables, and too many options.

But I will say, I'm not sure it could be done for much cheaper than $10k.

Enjoy a few Videos and pics from our DCT Projects-